Engine cooling fans draw air in through the vehicle's radiator to cool the coolant.

There are two types of cooling fans, mechanically driven and electric fans.

Mechanically driven fans are driven by the engines serpentine belt through the water pump while electric fans are

driven by an electric motor that is powered by the engine's electrical system.

Although electric fans are a load on the vehicle's electrical system they are more efficient than a belt driven fan.

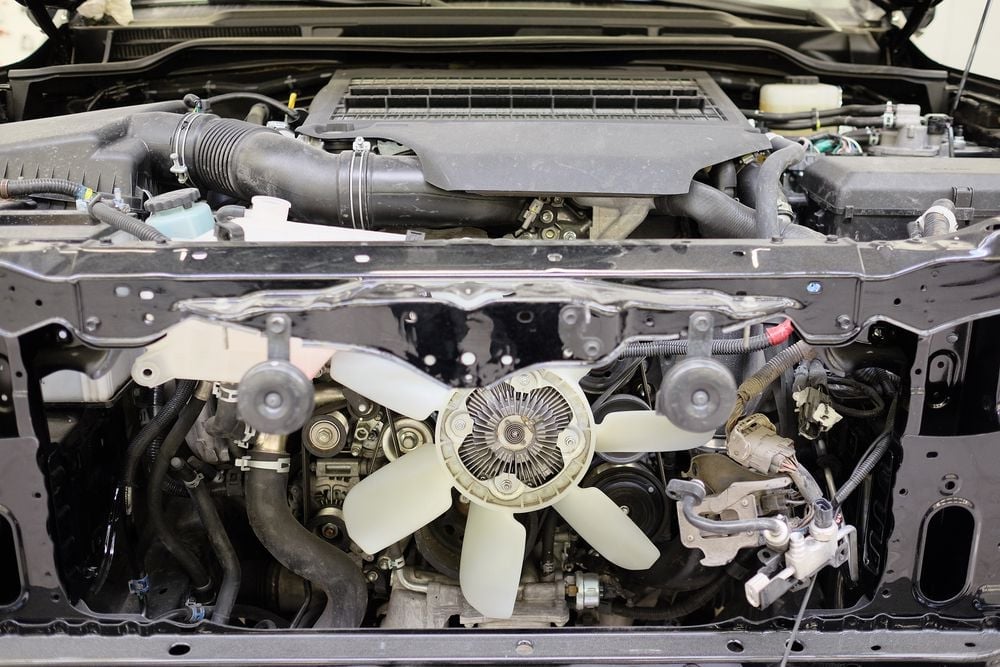

Engine Cooling Fan

Engine Cooling Fan

Thermal Vs. Non-Thermal Fan Clutch

The difference between a thermal fan clutch and a non-thermal fan clutch is that a thermal fan clutch is temperature

dependent while a non-thermal fan clutch is RPM dependent.

Thermal fan clutches are temperature dependent and use a bi-metallic spring to activate a valve plate. As the engine

heats up, the springs force increases against a valve plate which in turn opens a valve.

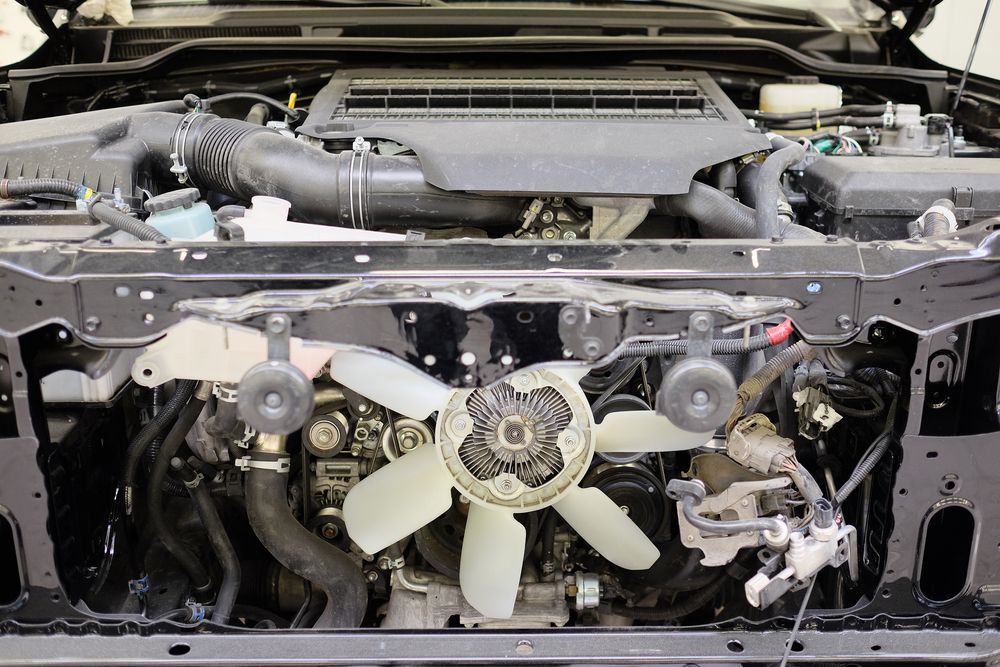

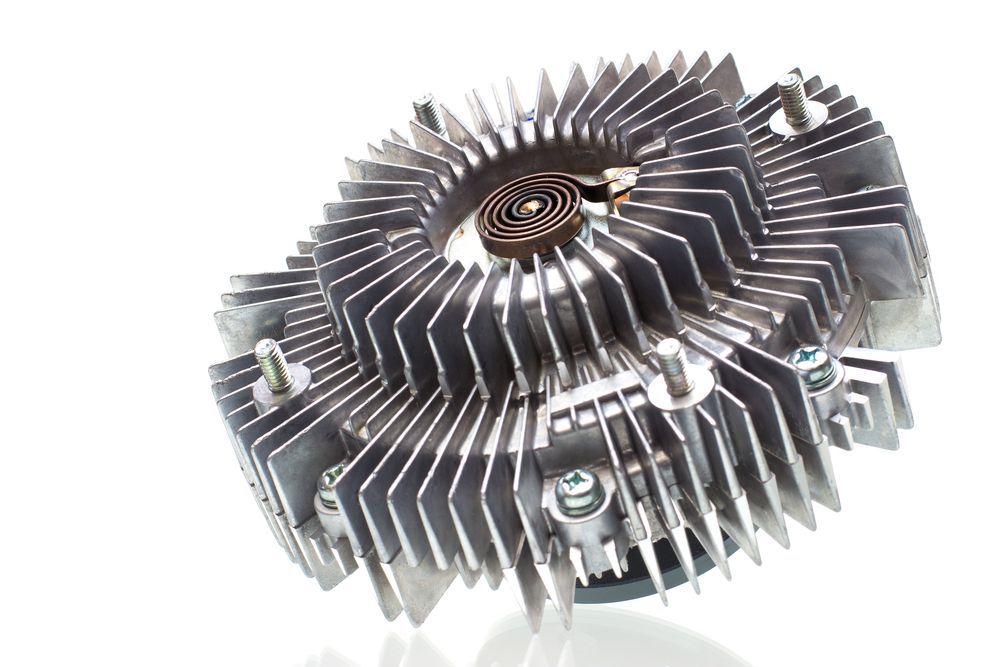

Thermal Fan Clutch

Thermal Fan Clutch

The open valve allows a silicon based oil to flow into the clutches working area which creates friction for the

clutch and engages the fan.

As the engine cools, the valve closes and the silicon oils flow is stopped which in turn disengages the clutch.

Thermal Clutch:

- higher cost

- higher life expectancy

- engages based on temperature behind radiator

- when engaged at high temp provides maximum cooling

- when disengaged provides better fuel efficiency

Non-thermal fan clutches are rpm dependent. Centrifugal force is used to open the clutches valve and which allows the

clutches oil to flow through the clutches working area and engages the clutch.

Non-Thermal Clutch:

- Shorter life expectancy

- Lower cost

- Always engaged, more noise and less fuel efficiency

Fan Clutch Vs. Direct Drive

A direct-drive fan (fixed fan) has no clutch and is run directly off the water pump output shaft.

This means that at

higher speeds the direct-drive fan spins extremely fast needlessly as sufficient air woold be flowing through the

radiator at high speeds.

The fast spinning creates excess noise and needless resistance leading to a decrease in

engine efficiency.

Engine Cooling Fan Clutch

Engine Cooling Fan Clutch

On the other hand, a fan clutch will slip at high speeds decreasing fan noise and increasing engine efficiency.

Clutch Fan Vs. Flex Fan

A flex fan is direct driven and runs at 100% of the water pump speed. The fan blades are designed to flatten out at

high rpm when natural airflow through the radiator due to the vehicle's speed will be sufficient to cool the engines

coolant.

When the fan flattens out it will be less of a load on the engine, increasing the engine's efficiency as opposed to

rigid fan blades.

Clutch Fan Vs. Mechanical Fan

There are two main types of mechanical fans (also known as belt driven fans). Clutch fans and flex fans. Clutch fan

speeds are controlled temperature activated clutch while flex fans are 100% controlled by the engine's water pump

rpm.

Clutch Fan Vs. Electric Fan

A clutch fan is belt driven by your vehicle's engine whereas an electric fan is powered by your vehicle's electrical

system.

The electric fan has no parasitic losses thereby giving you better horsepower and fuel economy but moves

less air flow at above 2400 rpm.

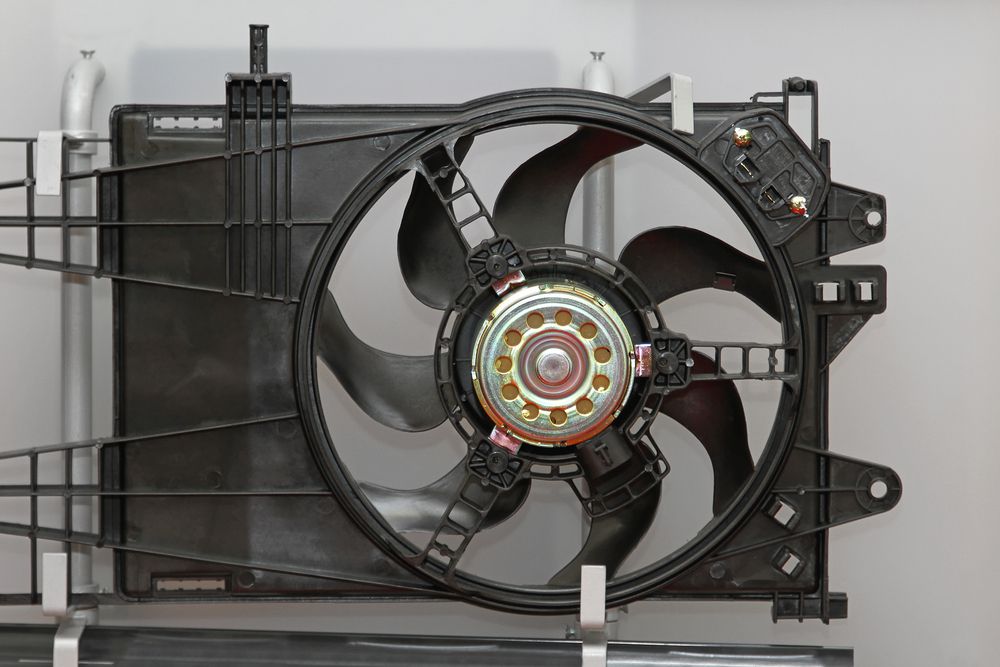

Electric car cooling fan

Electric car cooling fan

Due to the parasitic losses a belt fan will reduce your horsepower and fuel mileage

but will move more air at above 2400 rpm.

To reduce the parasitic losses in a clutch flan you can use a flex fan blade that will flatten at higher RPMs to

reduce drag.